Since 2003 until 2015, three independent plants for freeze- and vacuum drying of books, archive materials and other types of mobile cultural heritage have been installed at the shared location of ZFB and ZFB-PM in Leipzig. ZFB-PM has optimized those plants over years for a high performance with a possibly low energy consumption to enable an economic operation in the high-competitive conservation market. In the last decades for instance, harmed and endangered books after the fire at the Herzogin Anna Amalia library, the collapse of the Collogne City Archive or after several local flood catastrophes have been saved by a treatment in the in-house optimized freeze-drying process.

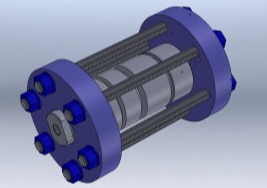

From 2004 to 2012, ZFB-PM developed and commissioned a novel industrial mass deacidification process for books and archive documents – the ZFB:2 process. Since 2012, the ZFB:2 plant with integrated vacuum drying and solvent recycling is successfully in operation and has by now after capacity expansions become the world’s largest mass deacidification plant for the treatment of archive documents and books which are endangered by acidic catalyzed degradation processes.

Furthermore, the portfolio of ZFB-PM includes the chemical development, process-engineering and production of sub-micro-dispersions, which can be used as e. g. deacidification agent (impregnation) or for the production of technical ceramics (ferrits).

In the past years, beyond that, we adressed microwave-based drying processes and have experiences in the construction and production of appropriate plants.

A further current focus is nanotechnology, especially the plant development for the production of nanocellulose (microfribrillated cellulose).

ZFB Project-Management GmbH (ZFB-PM) was founded in 2001 as affiliated company of the ZFB ZENTRUM FÜR BUCHERHALTUNG GmbH (ZFB), which was outsourced from the book conservation center of the German National Library in 1997. The focus of activities includes the development of innovative processes, plants and special machinery for the conservation treatment of mobile Cultural Heritage, especially paper based documents. ZFB Project-Management is your specialized partner for the development, construction, manufacturing, commissioning and process optimization of customized plants for freeze-drying and chemical treatments of books, followed by a gently vacuum drying. To provide sustainable treatments, a high percentage of the used solvents are recovered and recycled.

ZFB Project-Management GmbH (ZFB-PM) was founded in 2001 as affiliated company of the ZFB ZENTRUM FÜR BUCHERHALTUNG GmbH (ZFB), which was outsourced from the book conservation center of the German National Library in 1997. The focus of activities includes the development of innovative processes, plants and special machinery for the conservation treatment of mobile Cultural Heritage, especially paper based documents. ZFB Project-Management is your specialized partner for the development, construction, manufacturing, commissioning and process optimization of customized plants for freeze-drying and chemical treatments of books, followed by a gently vacuum drying. To provide sustainable treatments, a high percentage of the used solvents are recovered and recycled.